- Home Page

- Company Profile

-

Our Products

- Electrical Lighting Poles

- Conical Lighting Pole

- High Mast Lighting Poles

- Stadium Lighting Poles

- Stadium Mast Poles

- Steel Tubular Poles

- High Mast Poles

- Decorative Lighting Poles

- Swaged Tubular Poles

- Octagonal Lighting Pole

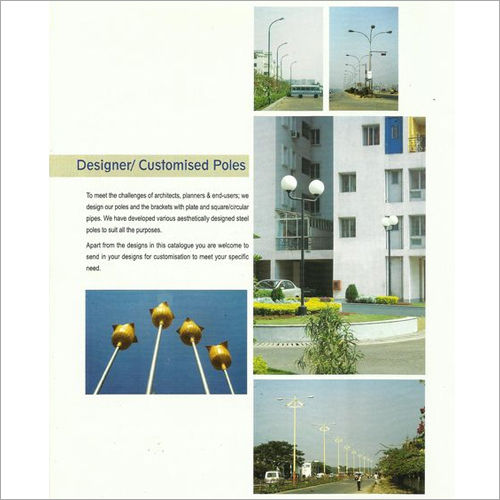

- Customized Design Poles

- Garden Lighting Poles

- Designer Lighting Poles

- High Mast Lighting System

- Hexagonal Lighting Poles

- High Mast Signage

- Decorative Arm Brackets

- Flag Poles

- Electrical Cable Tray

- Decorative Poles And Brackets

- High Mast Pole

- Electrical Lighting Poles

- Contact Us

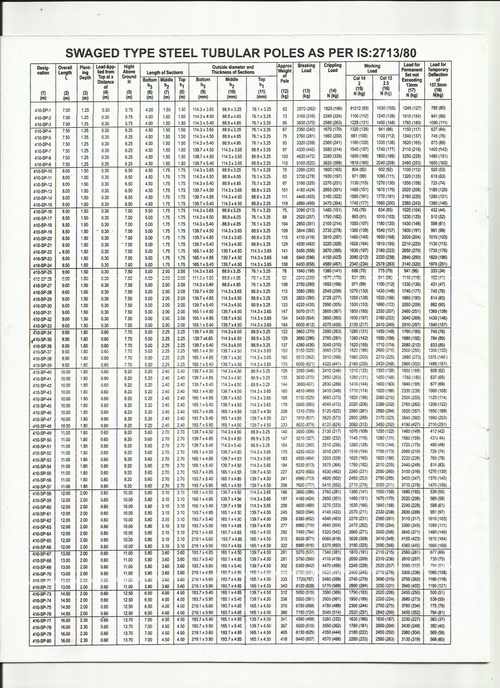

Swaged Tubular Poles

3000 INR/Piece

Product Details:

- Head Diameter 60 mm to 76 mm (top diameter as per specification)

- Power Not applicable (pole only, no electrical rating)

- Diameter 76 mm to 165 mm (bottom diameter as per IS:2713)

- Size Available in custom sizes as per IS:2713 (Part-I) and (Part-II)

- Dimension (L*W*H) Height varies (4 m - 12 m)

- Product Type Swaged Tubular Poles

- Material Mild Steel (MS)

- Click to View more

X

Swaged Tubular Poles Price And Quantity

- 10 Piece

- 3000.00 - 30000.00 INR/Piece

- 3000 INR/Piece

Swaged Tubular Poles Product Specifications

- Not applicable (pole only, no electrical rating)

- Mild Steel (MS)

- Black/Grey or as per client specification

- 76 mm to 165 mm (bottom diameter as per IS:2713)

- 4 m to 12 m

- Available in custom sizes as per IS:2713 (Part-I) and (Part-II)

- Height varies (4 m - 12 m)

- Corrosion resistant coated finish

- Swaged Tubular Poles

- 60 mm to 76 mm (top diameter as per specification)

- Outdoor lighting, street lighting, area illumination, parks, highways

Swaged Tubular Poles Trade Information

- kolkata

- 5000-10000 Piece Per Month

- 3 Week

- Truck Loaded

- Dadra and Nagar Haveli, Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, Chandigarh, Central India, West Bengal, Assam, East India, Pondicherry, Rajasthan, Haryana, Karnataka, Bihar, Telangana, Madhya Pradesh, Punjab, Tripura, Tamil Nadu, North India, Goa, Arunachal Pradesh, South India, Sikkim, Jharkhand, Meghalaya, Delhi, Jammu and Kashmir, Mizoram, Kerala, Gujarat, Uttar Pradesh, Maharashtra, Andhra Pradesh, Odisha, West India, Chhattisgarh, All India

- ISO 9001:2015

Product Description

Available in a myriad of dimensions, the Swaged Tubular Poles we offer are known for their durability and unrivaled service life. The poles are built using components and materials sourced from trusted vendors and thus are very durable. In order to reduce weight, the tube has a hollowed out center and can thus be transported and set up with ease. Furthermore, the poles are free from defects owing to stringent testing that is performed by a team of expert quality controllers.

Features of Swaged Tubular Poles:

- Tested extensively by expert quality controllers.

- Manufactured using heavy duty steel.

- Rust proof.

Designed for Durability and Versatility

Our swaged tubular poles are meticulously crafted for endurance in outdoor environments, with each pole engineered to hold up against demanding wind zones following IS:875 (Part III). Multiple sections are securely swaged and joined, resulting in exceptional strength and stability. The maintenance-free design and easy installation processes make these poles ideal for municipal, commercial, and public applications.

Customizable Finishes and Configurations

Clients can choose from hot dip galvanized, painted, or powder coated finishes to maximize corrosion resistance and suit aesthetic preferences. Pole height, diameter, and base configurations (direct embedment or flange plate) can be tailored for specific installation requirements. Flexible options result in superior adaptability for street lighting, parks, and highways.

FAQs of Swaged Tubular Poles:

Q: How are swaged tubular poles installed outdoors?

A: Swaged tubular poles can be installed either through direct embedment into concrete foundations or by using a flange plate for foundation bolt mounting, depending on the application and site requirements.Q: What are the available finish options for these poles?

A: Finishes offered include hot dip galvanized, painted, or powder coated surfaces. Each option is designed to enhance corrosion resistance and provide a long-lasting protective coating, suitable for various outdoor conditions.Q: Where can these poles be used effectively?

A: These swaged tubular poles are intended for outdoor locations such as parks, highways, area illumination projects, and general street or outdoor lighting, ensuring reliable performance in diverse public and private spaces.Q: What is the process for selecting the right pole size and specification?

A: Pole selection involves assessing site requirements, wind zone classifications per IS:875 (Part III), and desired mounting type. The height, tube thickness, and finish can be customized according to client needs while conforming to IS:2713 standards.Q: What benefits do swaged stepped joints offer?

A: Swaged stepped joints provide enhanced structural strength and rigidity, allowing for multiple pole sections to be securely connected. This design ensures reliable support and long service life under outdoor conditions.Q: Are these poles suitable for electrical applications or rated for power?

A: Swaged tubular poles are designed exclusively as supporting structures for lighting fixtures and do not carry any electrical ratings or power capabilities. They serve as robust supports in illumination projects.Q: What makes these poles maintenance-free?

A: The advanced protective finishes, combined with high-quality mild steel construction, minimize corrosion and reduce the need for ongoing maintenance, enabling worry-free operation throughout their service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email